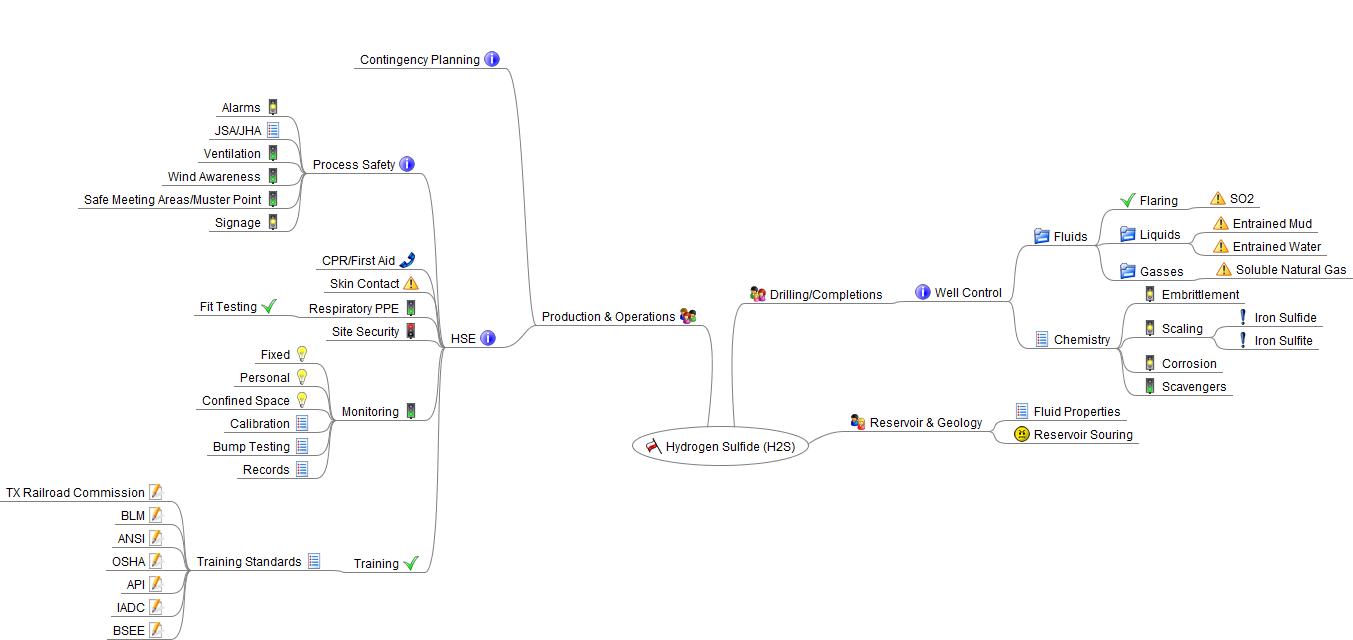

EAGLE FORD TRAINING SAN ANTONIO H2S TRAINING MIND MAP

H2S is a small and simple molecule yet it interacts with oil and gas processes in complex and varied ways. When the H2S molecule reaches the lungs of the oilfield worker in even small quantities the results can be fatal. It is imperative that appropriate protections be taken to prevent South Texas workers from being exposed to the harmful effects of H2S gas. H2S training and personal protective equipment form one line of defense, but there are multiple layers of hazards and protections brought about through the methods of well control and HSE. This mind map is created to help show how H2S can for these complex hazards within the petroleum disciplines and control methods.

DISCIPLINE BASED H2S AWARENESS

The three engineering disciplines describe the different ways that petroleum engineers approach oil and gas development. The first includes reservoir/geological engineering, which is concerned mainly with the extent of the reservoir rock and the fluid composition within. In earlier posts we discussed how reservoir characterizations can be important during frac hits, an H2S release disaster, as well as the possibility of reservoir souring under certain injection conditions. Drilling/completions engineering is a discipline concerned with the safe and efficient construction of wells that are able to hit their reservoir targets. Production/operations engineering is concerned with the fluid mechanics of lift and the safe efficient day to day operation of petroleum wells. With H2S, as with any challenge, these disciplines ideally will work together to mitigate hazards and successfully produce oil and gas across South Texas.

WELL CONTROL

As defined, well control seeks to keep the pressure in the wellbore greater than the reservoir without causing so much overbalance so as to cause lost circulation. More broadly, well control seeks to keep wellbore fluids circulating in a contained and controlled matter including oil, gas, water, and contaminants such as H2S. Preventing gas influxes, including H2S gas influxes, from entering into the wellbore in the first place gives well control an operational first line of defense against H2S in South Texas. When high levels of H2S are produced, however, they can attack drillstring tubulars and surface well control equipment with primarily carbon steel metalurgy. Well control supervisors working on H2S wells need to understand the effect of H2S on steel and the additional risk involved should a release occur.

HSE

Safety, or “Health, Safety, and Environment” (HSE) focuses on the interactions between hazards and individuals or the environment. This is an extremely important focus for any oil and gas operation. Workers need to be wearing personal protective equipment appropriate to the H2S hazard level, fitted, and trained how to use that PPE. Monitoring for H2S determines when to don this protection or to evacuate the area. Standards and regulations by various associations and regulatory bodies are also described during the training to help the workers through the right H2S training information in South Texas and other jurisdictions. Workers may also be required to be knowledgeable and certified in first aid, CPR, and resuscitator use.

PROCESS SAFETY

Process safety is a somewhat more proactive method of enacting HSE controls. The goals of process safety are to add extra lines of defense beyond personal protective equipment so workers are not exposed to H2S hazards at all. This is typically done by modifying the work-space to reduce the number of risks, although with the difficult nature of the oilfield the risks can be more challenging and unpredictable than the average work-space in San Antonio. There are certain controls that can work when H2S is present in rural South Texas oilfields, such as designating safe meeting areas, installing ventilation fans, and using wind awareness to the work-site’s advantage.

Map has been created with Free Mind Software.

Recommended Training: H2S Training in San Antonio, Industrial First Aid and CPR

Notice: Article is provided as is and for informational use only. Eagle Ford Training San Antonio, its owners, instructors, and affiliates hereto referred as the company shall have no liability for and you shall defend, indemnify and hold harmless from and against any claim loss demand, liability, obligation, and expense based upon any injury or damage, spill or pollution, product liability, or any other loss that may occur. The liability for the use of information is solely yours notwithstanding any act of error or omission by the company.

Anyone care to comment on H2S gas and loss circulation? H2S is a heavy gas. Anyone experience mitigation during loss returns or detection upon regaining flow only