Click Here for Free Online H2S Training at WWW.Oilfield.Training

HAZARD MEASUREMENTS

Previously we have written that sulfur dioxide (SO2) awareness should be included in a good H2S training program. One question that routinely comes up over the course of San Antonio H2S training regards the severity of the risk of Hydrogen Sulfide versus that of Sulfur Dioxide. In many oil and gas operations, hydrogen sulfide is flared to produce sulfur dioxide. Paradoxically, the threshold limit of SO2 is actually lower than that of H2S (20 PPM vs 10 PPM) and SO2 and H2S are actually Immediately Dangerous to Life and Health (IDLH) at equal concentrations (100ppm).

PHYSIOLOGICAL DIFFERENCES

Given that it has a lower threshold limit value, on first glance it would seem that SO2 is more dangerous than H2S, does it make any sense to flare hydrogen sulfide into sulfur dioxide in South Texas? To understand the issue, one needs to understand the physiological impacts that both chemicals can have on the human body. Sulfur dioxide is a concern due to it combining with water to become sulfuric acid—a strong acid. While exposures to acids are to be avoided at all times, it is when the S02 enters the lungs that it causes the greatest risk.

Hydrogen sulfide has the ability to create a weak acid—hydrosulfuric acid—but that is not generally the property that it is known for. The toxicity of H2S is largely dependent on its ability to shut down the nervous system. Perhaps the shortest and easiest explanations given these differences is that at lower levels sulfur dioxide can be described as a more corrosive irritant—especially when the lungs are concerned—and at moderately higher levels hydrogen sulfide can be described as an effective neurotoxin.

OVERALL PROCESS SAFETY

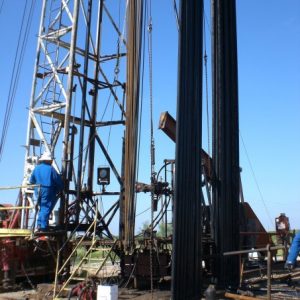

Given the physiological differences between the two gasses, flaring H2S into SO2 makes sense as an SO2 exposure ought to be easier to escape than H2S, all things being equal. There are some other process safety benefits to flaring that need to be included as well. The first includes diverting the gas offsite to increase the distance from the risk. Best practice would be to tend to avoid parking the company man trailer underneath the flare stack because this benefit disappears and other hazards increase, especially for the company man. This does happen and broaching the subject, however, can be politically risky. This poor location practice still retains the advantage that the height of the flare stack will still heat and disperse the gas upwards. Ensuring that exposures to toxic gases for all workers are minimized is of critical importance, so all best practices should be heeded.

Recommended Training: Online H2S Training

Notice: Article is provided as is and for informational use only. Eagle Ford Training San Antonio, its owners, instructors, and affiliates hereto referred as the company shall have no liability for and you shall defend, indemnify and hold harmless from and against any claim loss demand, liability, obligation, and expense based upon any injury or damage, spill or pollution, product liability, or any other loss that may occur. The liability for the use of information is solely yours notwithstanding any act of error or omission by the company.